Description

WNS series gas/oil fired steam boiler is horizontal three pass fire tube wet back full automatic steam boiler. It normally suitable for 500kg to 20ton/h capacity, use all kinds of gas and oil fuels,such as natural gas, lpg,lng,cng,city gas,biogas, diesel oil,heavy oil.

1.Model:WNS

2.Capacity:500kg, 1 ton,1.5 ton,2 ton, 3 ton, 4 ton, 5 ton,6 ton, 8 ton,10 ton, 12 ton, 15 ton,20 ton

3.Design pressure:1.0Mpa(10bar/10kg/145psi), 1.25Mpa(13bar/13kg/180psi), 1.6Mpa(16bar/16kg/232psi),2.5Mpa(25bar/25kg/362psi)

4.Steam temperature:184℃,194℃,205℃,226℃

5.Design fuel:natural gas, lpg,lng,cng,city gas,biogas, diesel oil,heavy oil

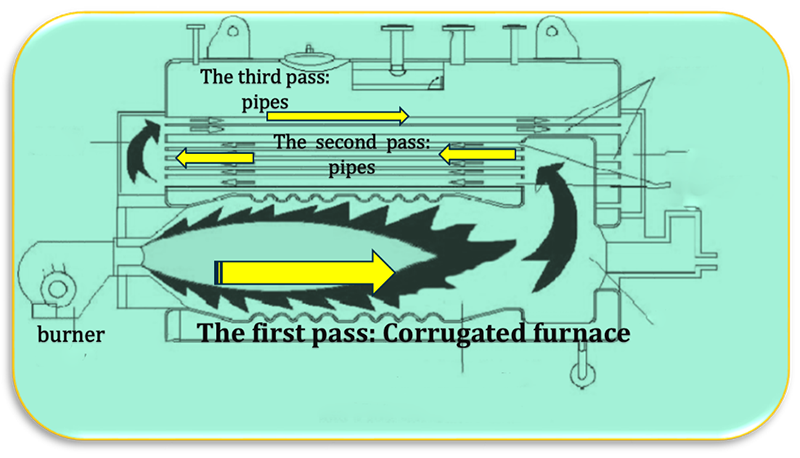

6.Structure: three pass fire tube wet back

1.High Efficiency

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

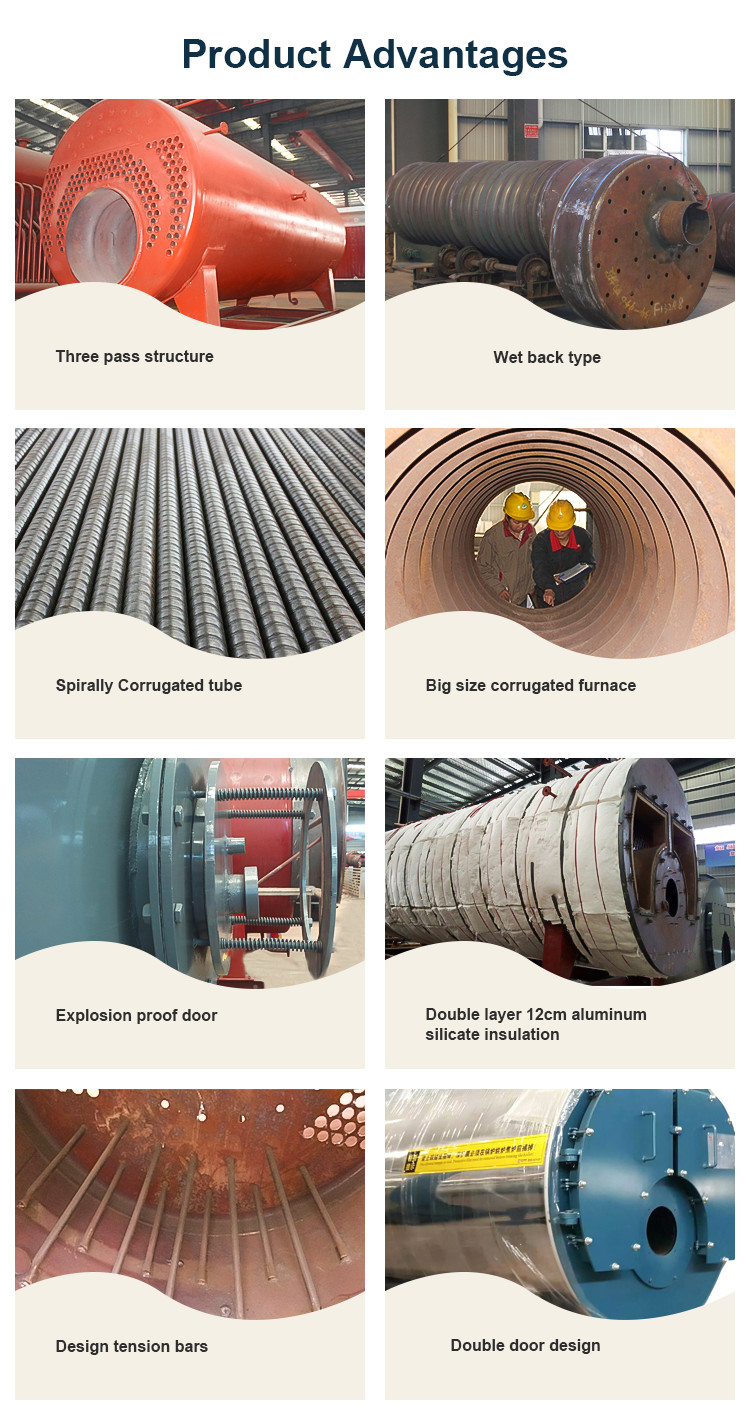

2) Adopts horizontal type three pass structure, absorbs the thermal expansion effectively. Uses large diameter corrugated furnace, large combustion space, high combustion efficiency.

3) The spirally corrugated tube strengthen the disturbance of flue gas, high heat transfer efficiency.

4) The boiler shell use aluminium silicate board for heat preservation, low heat loss.

5) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency could be increased to as high as 97%.

2. High Safety Performance

1) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

2) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

3) Equipped with explosion proof equipment, discharge high energy when deflagration happened in furnace, to ensure the boiler operate safety and efficiently.

3. Full Automatic Control

Adopts PLC full automatic intelligent control cabinet and interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

4. Low Cost

1) Adopts proprietary technology of Mer Boiler, the boiler is 100% butt welding, high quality, and long working life, low maintenance fee.

2) The boiler has high combustion efficiency,energy saving, and low cost on fuel.

5. Save Space

Adopts fast assemble structure, compact structure, convenient for transportation, small occupation.

6. Convenient Maintenance

1) There are manhole, head hole, and special hand hole on the boiler. The front and back smoke chambers are equipped with movable doors, convenient for boiler internal installation, inspection and clean.

2) The explosion proof door has the fire sight glass and inspection gallery, convenient for furnace checking and maintaining.

Specification

Boiler model | Rated capacity | Rated | Rated steam tempe | Fuel consumption | Thermal effiency | Weight | Diemension | |||

natural gas | Diesel oil | heavy fuel oil | lpg | |||||||

ton/h | Mpa(bar) | ℃ | m3/h | kg/h | kg/h | m3/h | % | ton | mm | |

WNS0.5-1.0-Y(Q) | 0.5 | 1(10) | 184 | 43 | 33 | 34 | 14 | 92 | 3 | 3000*1500*1800 |

WNS1-1.0-Y(Q) | 1 | 1(10) | 184 | 80.2 | 65.5 | 67.3 | 29 | 92 | 4.3 | 3561*1690*1910 |

WNS1.5-1.25-Y(Q) | 1.5 | 1.25(13) | 194 | 120.5 | 98.5 | 100.2 | 43.5 | 92 | 5.6 | 3681*1870*1980 |

WNS2-1.25-Y(Q) | 2 | 1.25(13) | 194 | 165 | 129.6 | 132.2 | 57.3 | 92 | 7.2 | 4111*1950*2199 |

WNS3-1.25-Y(Q) | 3 | 1.25(13) | 194 | 250 | 192 | 195 | 82 | 92.5 | 8 | 4330*2248*2564 |

WNS4-1.25-Y(Q) | 4 | 1.25(13) | 194 | 323.6 | 256 | 261.9 | 109 | 93 | 9.6 | 4732*2150*2448 |

WNS5-1.0-Y(Q) | 5 | 1.25(13) | 194 | 386 | 318 | 322 | 140 | 93 | 12.5 | 5970*2360*2796 |

WNS6-1.25-Y(Q) | 6 | 1.25(13) | 194 | 450 | 380 | 390.6 | 164 | 93.5 | 16.5 | 5500*2600*2990 |

WNS8-1.25-Y(Q) | 8 | 1.25(13) | 194 | 642 | 503 | 517 | 209 | 93.5 | 24.8 | 6450*2800*3200 |

WNS10-1.25-Y(Q) | 10 | 1.25(13) | 194 | 805 | 628 | 643 | 264 | 94 | 26.8 | 6800*2900*3394 |

WNS12-1.25-Y(Q) | 12 | 1.25(13) | 194 | 970 | 758 | 775 | 321 | 94 | 32 | 7050*3100*3450 |

WNS15-1.25-Y(Q) | 15 | 1.25(13) | 194 | 1185 | 940 | 965 | 400 | 94.5 | 38 | 7150*3200*3540 |

WNS20-1.25-Y(Q) | 20 | 1.25(13) | 194 | 1597 | 1250 | 1301 | 520 | 94.5 | 55 | 8200*3400*3826 |

Notice: | ||||||||||