Description

Introduction of SZL series double drum coal fired steam boiler

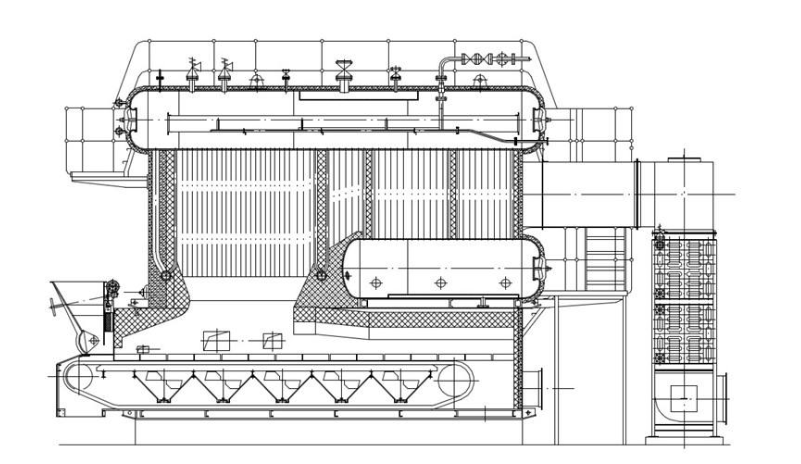

SZL series coal/biomass chain grate boilers with high efficiency, strong overload capacity and various fuel adaptability (biomass pellets or coal), are well known as the best design among contemporary domestic similar products and have reached the world's advanced level. The boiler is mainly composed of upper and lower drums, convection tubes, water-cooling wall tubes, down pipes and headers. The upper and lower drums are arranged longitudinally and with belt type chain grate as its combustion equipment and non-polar speed-changing device drivers. The boiler proper is composed of upper and lower longitudinal drums and convection tubes. With the arrangement of the Φ51*3 pipes in the combustion chamber as the water-cooling wall, water-steam separation device and continuous sewage device in the upper drum and periodical sewage device in the lower drum for assure steam quality. Equipped continuous automatic feeding water device for making sure that the boiler can be safely operated. The economizer is laid at the end of the boiler.

Main Features of szl series double drum coal fired steam boiler

1. By adopting the water-cooling system in packaged boilers which is usually used in power plant boilers, the boiler can achieve large heat transfer area, high heat transfer efficiency, low heat loss, good air tightness, and no distortion or dust leakage of the brickwork.

2. The front and back water-cooling wall tubes stretch themselves to the upper side of the chain grate, which increases the heating surface and overload capacity. The frames of the front and the rear arch are made of water-cooling tube wall, together with high-alumina cement, which can avoid the defects of the cracking and collapsing of the arch and extend its lifespan.

3. The distance between the front shaft and the rear shaft of the grate stoker is longer than other similar type domestic products. In this way, the combustion time of the fuel in the furnace is extended and the fuel combustion is more sufficient and the carbon content in the slag is decreased. Meanwhile, the actual heating surface of the grate is increased and the overload capacity is remarkably enhanced.

4. There are six independent wind chambers arranged lengthways and each chamber has an independent air adjuster, which can respectively adjust the air volume in each chamber so as to achieve the best combustion effect.

Specification

Steam Boiler | Rated steam | Rated working | Feed water | Rated steam | Boiler efficiency | Coal |

SZL10-1.25(2.5)-AII | 10 | 13/25 | 105 | 194/226 | 81 | 12.4 |

SZL15-1.25(2.5)-AII | 15 | 13/25 | 105 | 194/226 | 81 | 15.3 |

SZL20-1.25(2.5)-AII | 20 | 13/25 | 105 | 194/226 | 81 | 21 |

SZL25-1.25(2.5)-AII | 25 | 13/25 | 105 | 194/226 | 81 | 24.3 |

SZL30-1.25(2.5)-AII | 30 | 13/25 | 105 | 194/226 | 81 | 31.8 |

Model | boiler proper and chain grate shipped separately SZL "A" design coal fired steam boilers for | |||||